Crafting the Perfect Ring: A Comprehensive Guide

Creating a gold ring is a harmonious blend of artistry, technology, and craftsmanship. Whether it’s an engagement ring, a wedding band, or a statement piece, each step contributes to the final masterpiece. Let’s explore the intricate process of making a gold ring:

1. Design and Inspiration

- Begin by envisioning your dream ring. Consider style, gemstones, and overall aesthetics.

- Sketch your design or use computer-aided design (CAD) software to create a detailed blueprint.

2. Sizing and Customization

- Unlike pre-made rings, we don’t compromise on fit. We size your ring in CAD, ensuring a precise fit.

- Custom details, such as engravings or unique features, are seamlessly integrated into the design.

- The structural integrity remains intact, especially around settings for diamonds and side stones.

3. Creating the Wax Model

- We 3D print a wax model of the ring using the CAD design.

- This physical prototype allows us to visualize the final product and make necessary adjustments.

4. Mold Creation

- A specific plaster surrounds the wax model, creating a mold.

- For high-volume production, multiple wax models may be arranged like a tree.

- After hardening, the mold is baked at high temperatures, evaporating the wax and leaving a cavity imprint.

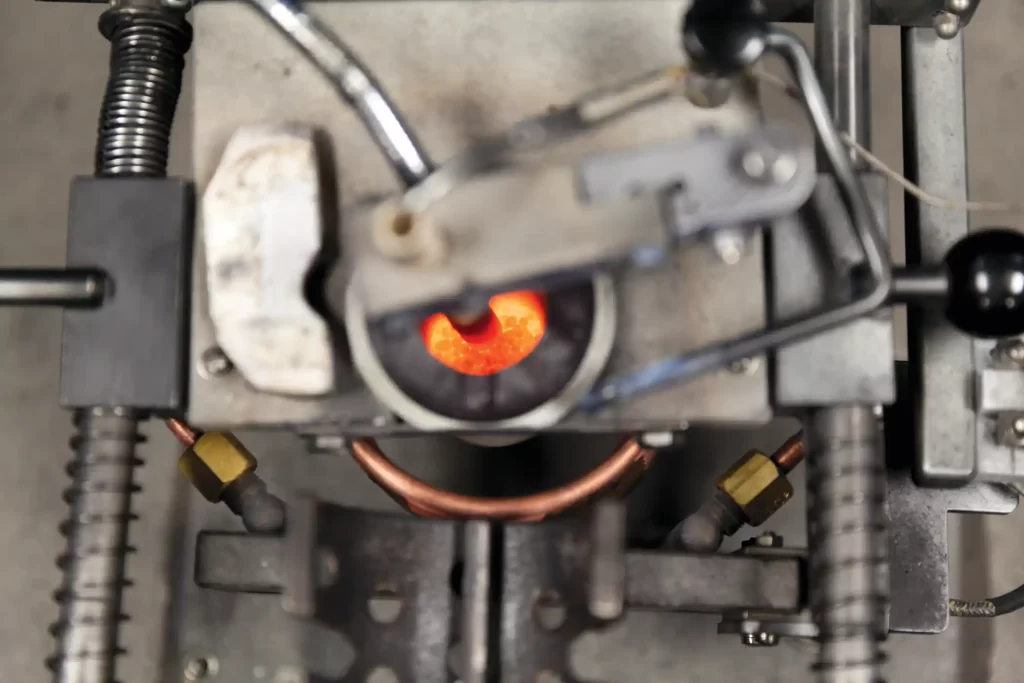

5. Casting in Precious Metals

- The mold is filled with hot molten metal (gold, in our case).

- The metal hardens, forming a raw casting.

- Vacuum chambers are often used to eliminate air spaces and imperfections.

- The mold can create several identical rings from the same pattern.

6. Polishing and Finishing

- Each raw cast piece is individually polished.

- The goal: a flawless surface and consistent shine.

- Attention to detail ensures a high-quality finish.

7. Stone Setting

- If your design includes gemstones, this step is crucial.

- The jeweler customizes the setting to snugly hold the center stone (e.g., a diamond).

- Prongs, bezels, or channels are meticulously positioned.

8. Final Touches: Rhodium Plating

- The ring undergoes fine polishing and buffing.

- For white gold settings, rhodium plating provides a brilliant, durable finish.

9. Quality Assurance

- A rigorous inspection ensures perfection.

- Craftsmanship, stone security, and overall aesthetics are scrutinized.

10. Presentation

- Your gold ring is packaged beautifully.

- Consider adding a certificate of authenticity.

Remember, each gold ring tells a unique love, commitment, and individuality story. Contact us today to learn more or begin your custom ring journey!